Maximizing Farm Efficiency: The Ultimate Guide to Farm Equipment Repair and Farming Equipment Maintenance

In the dynamic world of agriculture, the backbone of successful farming operations lies in maintaining and repairing essential farming equipment. Proper upkeep ensures smooth operations, reduces unexpected downtime, and maximizes crop yields. At TSGC Inc., we understand the importance of keeping your farm machinery in top condition, whether you’re managing planting, harvesting, or post-harvest processes.

Understanding the Significance of Farm Equipment in Modern Agriculture

Farm equipment encompasses a wide array of machinery and tools designed to improve productivity and efficiency on the farm. From tractors, plows, and combines to specialized attachments like seed drills and sprayers, these machines are vital for modern agriculture. Their proper maintenance not only extends equipment lifespan but also enhances operational safety and effectiveness.

The Critical Role of Farming Equipment Maintenance

Regular maintenance is the foundation of any effective farming operation. It involves routine inspections, timely repairs, and adherence to manufacturer guidelines. A well-maintained farm machine reduces fuel consumption, minimizes repair costs, and prevents costly downtime during critical planting or harvest windows.

Farm Equipment Repair: Keep Your Operations Moving

Despite best efforts, equipment failures may occur due to wear and tear, unforeseen damage, or improper use. Immediate repair services are crucial to ensure minimal disruption. Partnering with experienced professionals like those at TSGC Inc. guarantees prompt, expert repair work that restores equipment to optimal condition.

Key Components of Effective Farm Equipment Repair

- Diagnostic Accuracy: Using advanced tools to pinpoint issues precisely.

- Part Quality: Utilizing genuine or high-quality replacement parts for longevity and performance.

- Technical Expertise: Skilled technicians familiar with various machinery brands and models.

- Timely Intervention: Scheduling repairs early to prevent collateral damage and extend equipment life.

Maintaining Optimal silo temperature for Crop Preservation

One of the essential aspects of farming equipment management involves the silo temperature regulation. Proper control of silo temperature is vital to prevent spoilage, insect infestation, and mold growth in stored grains and feed. Grain silos need to maintain a consistent temperature close to the ambient environment to preserve quality and ensure safe storage.

Fluctuations or elevated silo temperature can indicate issues such as:

- Residual moisture causing fermentation or mold growth

- Biological activity within stored grain

- Equipment malfunction in aeration systems

Monitoring and managing silo temperature requires specialized equipment like temperature sensors and aeration systems. Regular inspections and maintenance of these systems by trained technicians can greatly reduce storage losses and improve overall farm profitability.

Choosing the Right Farming Equipment for Your Operation

Factors to Consider When Selecting Equipment

- Farm Size and Scale: Larger farms may require high-capacity machinery, while smaller farms benefit from specialized, versatile equipment.

- Crop Type: Equipment should be tailored to specific crops, whether grains, vegetables, or fruits.

- Budget and Cost-Effectiveness: Balancing cost with durability and efficiency to maximize return on investment.

- Technological Compatibility: Incorporating modern features such as GPS guidance, automation, and data management.

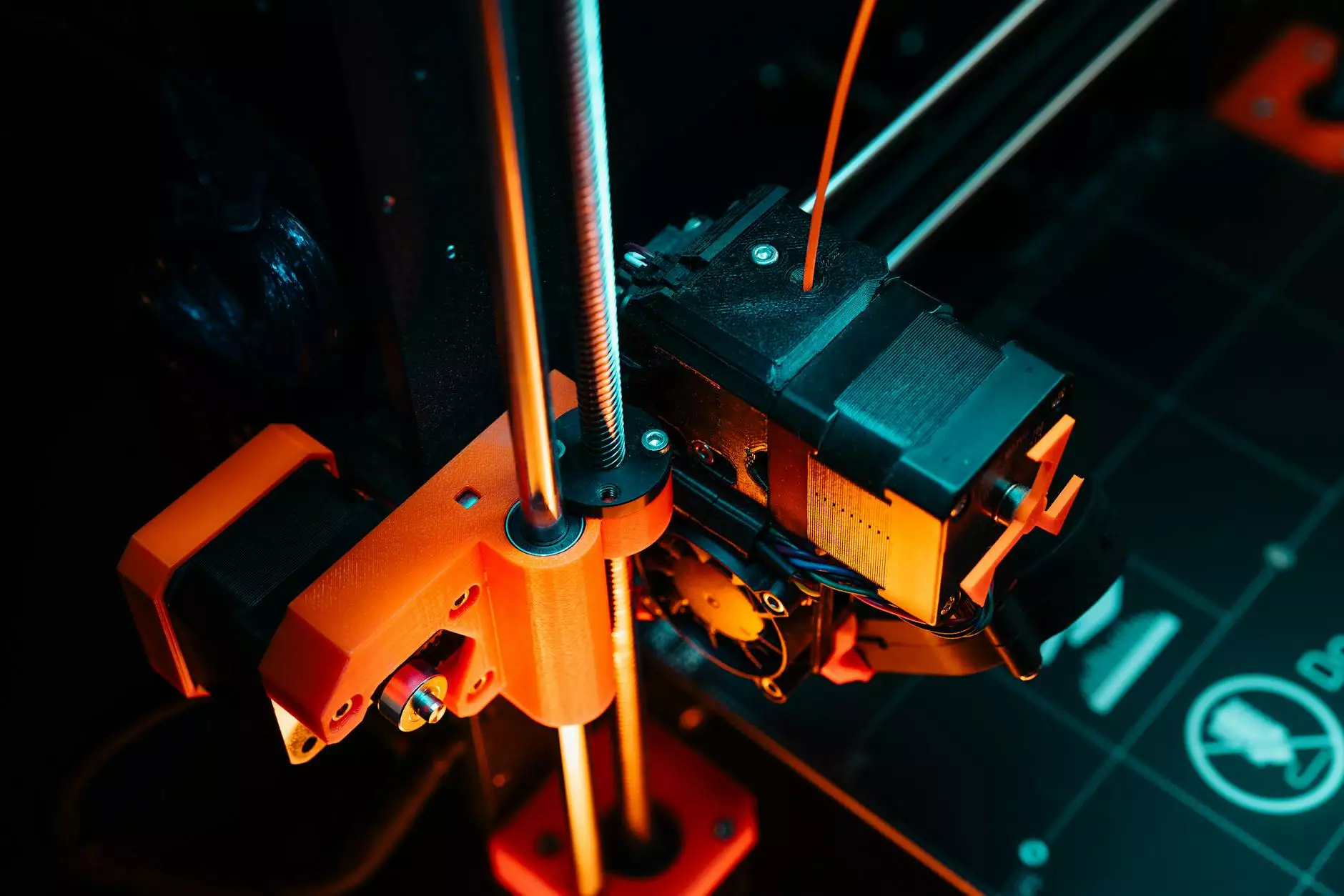

Innovations in Farming Equipment and Repair Technologies

Advances in technology continue to transform agriculture. Drone surveying, GPS-guided machinery, and IoT-enabled sensors allow for precision farming. These innovations improve planting accuracy, resource management, and machinery diagnostics, leading to more sustainable and profitable operations.

Similarly, repair processes benefit from technological integrations, with diagnostic software capable of detecting issues remotely, reducing repair times significantly. At TSGC Inc., we incorporate these cutting-edge tools to provide top-tier repair and maintenance services, ensuring your equipment performs at its best.

The Importance of Regularly Monitoring and Maintaining Silo Temperature

Maintaining optimal silo temperature is not a one-time task but an ongoing process. It involves:

- Consistent Monitoring: Using digital temperature sensors to track thermal changes within stored grain.

- Effective Aeration: Ensuring uniformly distributed airflow to regulate temperature and moisture levels.

- Routine Inspections: Checking for signs of spoilage, insect intrusion, or equipment malfunction.

- Prompt Response: Acting swiftly to adjust aeration or carry out repairs if abnormal silo temperature readings occur.

Effective management of silo temperature directly correlates with reduced grain spoilage, improved quality, and enhanced profitability. Proper training for farm staff on silo management and engaging specialist repair services ensures these systems function flawlessly.

Robust Support and Maintenance Plans by TSGC Inc.

At TSGC Inc., we understand that preventative care saves money and time. Our comprehensive service packages include:

- Scheduled Maintenance: Routine inspections and tune-ups designed to extend equipment lifespan.

- Emergency Repairs: Rapid response team ready to fix unexpected breakdowns.

- Parts Supply: Access to high-quality components for all major brands and models.

- Training & Consultation: Educating farm operators on proper equipment use and silo temperature management.

Strategies for Enhancing Your Farming Equipment Longevity

To ensure your machinery remains productive over the years, follow these expert tips:

- Adhere to Maintenance Schedules: Stick to the manufacturer's recommendations for inspections and replacements.

- Practice Proper Usage: Train operators to handle equipment correctly, avoiding unnecessary wear.

- Invest in Quality Parts: Use OEM-approved components to prevent compatibility issues and failures.

- Keep Records: Maintain detailed logs of maintenance and repairs for future reference and warranty claims.

- Monitor Conditions: Regularly assess environmental factors like humidity, temperature, and storage conditions, especially relating to silo temperature.

Partnering with Experts in Farm Equipment Care

Achieving peak performance from your farm machinery demands expert knowledge and reliable service. TSGC Inc. offers industry-leading expertise in farm equipment repair and farming equipment maintenance. Our team is highly skilled in diagnosing issues, implementing solutions, and advising on best practices for equipment longevity, including advanced silo temperature management techniques.

Conclusion: Elevate Your Farming Operations Today

Efficient farming is rooted in meticulous equipment care, strategic maintenance, and innovative management practices. Whether it's keeping your machinery running smoothly or ensuring optimal silo temperature conditions, every aspect counts in maximizing productivity and profitability.

Partner with TSGC Inc. for expert Farm Equipment Repair and Farming Equipment solutions tailored to your unique needs. Embrace technology, follow best practices, and invest in quality maintenance to stay ahead in today’s competitive agricultural landscape.

Take action now—protect your investments, improve your yields, and grow your farm’s success with trusted professionals committed to excellence in farm equipment care.